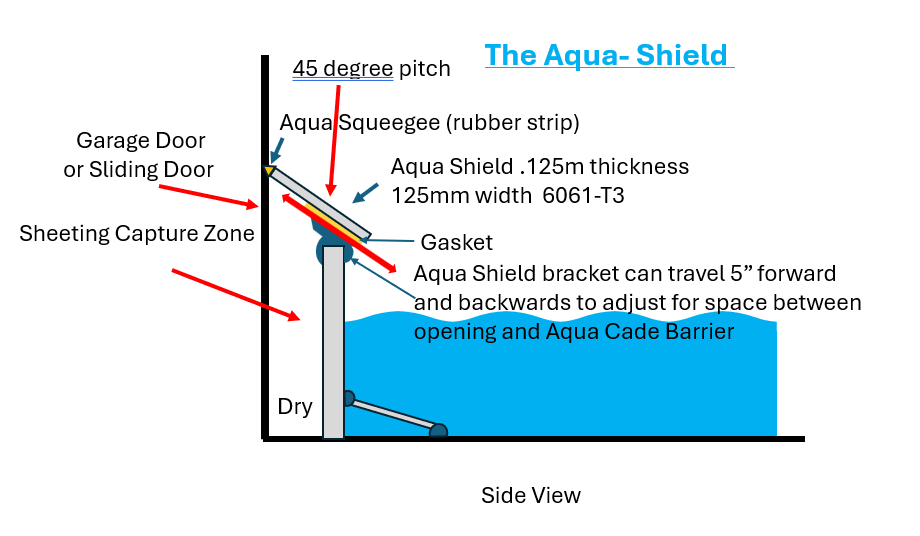

When you think about protecting your home, what comes to mind? Maybe it’s a security system, impact-resistant windows, or a sturdy roof. These are all critical, of course, but what if I told you that one of the most important components—a true unsung hero—is something you can’t even see? I’m talking about the gasket, the thin, flexible strip that seals the gaps in your windows and doors.

You might be thinking, “A gasket? Really?” Trust me, I get it. It’s not the flashiest part of your home, but after years of extensive research and hands-on experience, I can tell you that the type of gasket you use makes all the difference in the world. It’s the last line of defense against the elements, and in a place like Florida, where we face extreme heat, heavy rain, and even hurricanes, that defense better be rock solid.

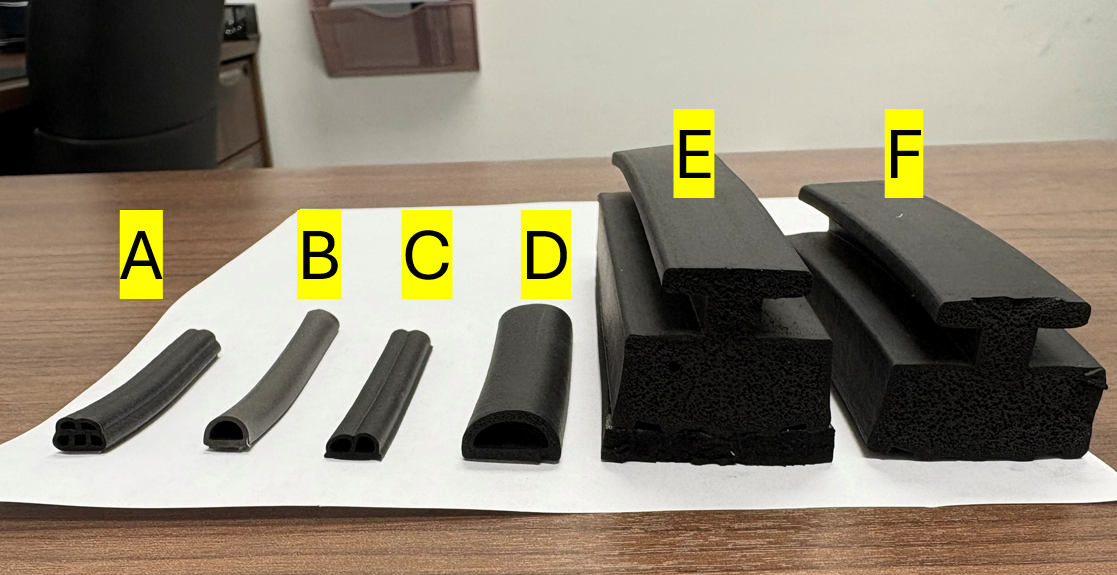

For a long time, the industry has relied on standard rubber materials. They get the job done, but just barely. We knew we could do better. So, we dug deep, pushing past the conventional wisdom to find something truly superior. We’re not about just meeting standards; we’re about setting a new bar for protection.

That’s what led us to a groundbreaking material: a special type of closed-cell neoprene known as CR/SBR Blends with Tin(II) Oxide Cross-linking, or CR/SBR Blends for short. This isn’t just a fancy name; it’s a material engineered to offer a level of protection that you simply won’t find in other gaskets.

What Makes Our Gasket Material So Different?

Let’s break down why we chose this specific material and how it provides unmatched protection for your home.

1. Superior Sealing and Chemical Resistance

Your home’s windows and doors are constantly exposed to a variety of substances, from cleaning agents and pesticides to everyday air pollutants. A standard gasket can degrade over time, leading to leaks and a loss of efficiency.

Our CR/SBR Blends are different. The material’s unique cross-linked network structure creates a formidable barrier that is highly resistant to chemical attack, especially from petroleum products. We’ve seen it perform under intense conditions, showing minimal swelling in various solvents like toluene and n-heptane. This means the gasket maintains its original size and shape, ensuring the seal remains intact year after year. The chloroprene rubber in the blend gives it an inherent resistance to oils, and the tin(II) oxide cross-linking creates additional chemical bonds that prevent oil penetration. Simply put, this gasket isn’t just a physical barrier; it’s a chemical one, too.

Enhanced Chemical Resistance

- The cross-linked network structure provides superior resistance to chemical attack like petroleum products.

- Reduced swelling in various solvents (toluene, 2-butanone, n-heptane) indicates better dimensional stability when exposed to fluids

- Lower equilibrium swelling values suggest maintained seal integrity

Superior Oil Resistance

- Chloroprene rubber component provides inherent oil resistance

- Cross-linking with SnO creates additional chemical bonds that resist oil penetration

2. Built to Handle Florida’s Extreme Heat

If you live in Florida, you know our summers are no joke. The intense sun can bake everything, and materials that aren’t built to withstand extreme temperatures will fail. This is where our gasket truly shines. The cross-linking process gives the material an incredible thermal stability, with a temperature range from 125°C to 243°C (that’s 257°F to 469°F!). This means it maintains its elasticity and sealing properties even on the hottest days, preventing it from becoming brittle or cracking. A gasket that can’t handle the heat will quickly lose its seal, compromising your home’s energy efficiency and inviting moisture and pests inside. With our gasket, your home stays sealed and protected, no matter how high the mercury rises.

Temperature Stability

- Cross-linking temperature range of 125-243°C indicates thermal stability- Critical in Florida’s extreme summer climates

- Maintains elastomeric properties across wide temperature ranges critical for gasket applications- Critical in Florida’s extreme summer climates

3. Mechanical Strength and Adaptability

A gasket’s job isn’t just to sit there; it has to be dynamic. It must conform to the surfaces it’s sealing, even if those surfaces aren’t perfectly flat. Think about stucco, for example—its high-relief texture can be a real challenge for most gaskets.

Our material has an extraordinary elongation capability of over 800%. What does that mean in plain English? It means it can stretch and conform to every tiny crevice and imperfection on a surface, ensuring a perfect seal. It’s like a custom-fit glove for your window or door frame. This high elasticity is also critical for accommodating the constant thermal expansion and contraction that happens with temperature changes. A gasket that isn’t elastic enough will lose its seal as the materials around it expand and contract. Ours, however, maintains its sealing force, no matter what.

It also has optimal compression set resistance. This is a fancy way of saying it won’t flatten out and lose its shape over time. The high degree of cross-linking creates a permanent network structure that resists permanent deformation under sustained compression. So, you can be sure that the seal will hold strong for years to come.

Excellent Elasticity

- Elongation capabilities >800% provide exceptional conformability to sealing surfaces- this helps with high relief stucco patterns.

- High elasticity ensures gaskets can accommodate thermal expansion/contraction cycles-offers excellent surface conformance to many surfaces.

- Maintains sealing force even with surface irregularities or dimensional changes- critical for sealing all types of surfaces.

Optimal Compression Set Resistance

- High degree of cross-linking (evidenced by torque increments up to 21.1 dNm) creates permanent network structure

- Resists permanent deformation under sustained compression loads

Controlled Hardness Range

- Stress values at 100% elongation (0.4-1.0 MPa) provide appropriate stiffness for sealing applications

- Balance between flexibility for surface conformance and rigidity for structural integrity

- Adjustable through blend ratio optimization

4. Safety and Environmental Responsibility

At the end of the day, we’re not just building a product; we’re building trust. And part of that trust is ensuring that what we put in your home is safe.

Our gasket material is non-flammable, with an oxygen index of 31%. This means it’s self-extinguishing and won’t contribute to the spread of a fire. This is a huge benefit for homeowners and can even help reduce insurance burdens.

But we didn’t stop there. We also made a conscious choice to eliminate zinc oxide, a common ingredient in traditional rubber manufacturing, to address growing environmental and worker safety concerns. Instead, we use a minimal amount of tin(II) oxide, which is safer for everyone involved, from the manufacturing floor to your home. This commitment to safety and sustainability is part of our core philosophy.

Fire Resistance

- Oxygen index of 31% classifies material as non-flammable

- Self-extinguishing properties eliminate fire propagation risk

- Reduces insurance and regulatory compliance burdens

Reduced Toxicity

- Eliminates zinc oxide, addressing environmental and worker safety concerns

- Lower SnO content (0.25-0.75 phr) reduces overall chemical exposure

- Meets increasingly stringent automotive and industrial safety standards

5. Durability and Cost-Effectiveness

We all want a product that lasts, and our gasket delivers. Its exceptional durability and long service life mean fewer replacements and reduced maintenance over time. While the initial investment might be slightly higher than a standard gasket, the long-term savings are significant. You won’t have to worry about leaks, drafts, or high energy bills from a failing seal. Plus, our material’s ability to meet stringent safety and environmental standards means it’s a superior, future-proof choice.

Application-Specific Advantages

Industrial Sealing

- Pipeline gaskets: Chemical resistance and long-term durability

- Pump seals: Oil resistance and mechanical integrity under dynamic conditions

- Reactor vessel seals: Chemical resistance and high-temperature performance

Electrical Applications

- Cable glands: Flame resistance and environmental protection

- Enclosure seals: Weather resistance and electrical insulation properties

- Switch gear gaskets: Fire safety and chemical resistance

Economic Benefits

Cost Effectiveness

- Lower cross-linking agent consumption reduces material costs

- Reduced need for flame retardant additives

- Extended service life reduces replacement frequency and warranty claims

Market Drivers

- Environmental compliance advantages in regulated markets

- Premium pricing potential for flame-resistant applications

- Differentiation from standard rubber gasket products

Recommended Gasket Applications

Optimal Use Cases:

- Automotive engine and transmission seals

- Industrial pump and valve gaskets where fire resistance is critical

- Chemical processing equipment seals

- Electrical enclosure gaskets requiring flame resistance

- Oil and gas industry sealing applications

My Final Takeaway

The material shows particular promise for gasket applications requiring the combination of chemical resistance, flame safety, and mechanical durability, especially in automotive and industrial environments where environmental compliance is increasingly important.

The above attributes across the board are we prefer this type of rubber.

If you’re thinking about the long-term protection of your home, don’t overlook the small details. The right gasket can make all the difference.